A Career with BFE

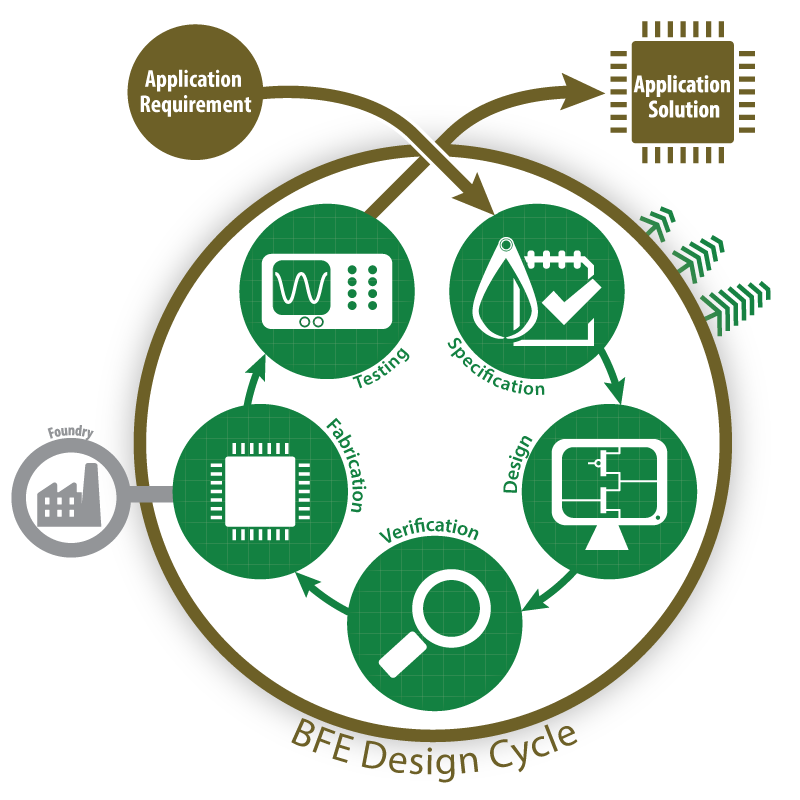

BFE continuously looks for engineering talent that could complement our already diversely competent and experienced group of designers. Every engineer at Black Forest Engineering must have a solid grasp of fundamental properties and design concepts. BFE engineers must also have the creativity to come up with the simplest and most easily implemented solution, providing for successful and robust designs.

BFE is an equal opportunity employer. All applicants will be considered for employment without regard to race, color, ancestry, national origin, sex, gender, sexual orientation, marital status, religion, age, disability, gender identity, results of genetic testing, service in the military, or any other characteristic protected by applicable federal, state or local laws. We will make a reasonable accommodation for any qualified applicant with a disability, provided that the individual is otherwise qualified to safely perform the essential functions of the job with or without accommodation and that the accommodation would not impose an undue hardship on the operation of our business. Please let us know if you believe you require reasonable accommodation, or if you would like assistance to complete an application or to participate in an interview at the company.