Decades of Experience

i >350 fully custom ICs

b Over 30 years of experience

jOver 15 different silicon foundries

cProcess experience ranging 60nm-1.2um

pInfrared camera development

fTest system development

kApplications

- IR detectors / preamplifiers / multiplexers

- LIDAR detectors & readout

- Laser drivers

- Photonic counting circuits

- Micro-power A/D and D/A converters

- Column parallel to 16-bit resolution (voltage- or time-to-digital)

- In-pixel ADC to 18-bit resolution

- Sigma-delta to 20-bit resolution for linear array

- X-ray and high energy particle detectors and interface chips

- Radiation hard versions of above

- Image sensors (CMOS and CCD)

- Image processors

- Integrated liquid crystal drivers

bChip Size Extremes

- 300um diameter die size imagers for medical applications

- 17×19 mm2 display driver for projection displays

- 51×25 mm2 visible/scintillator x-ray sensor (using stitching)

gDesign Types &

- 2Ghz analog bandwidth CMOS for LiDAR range sensing

- TDC (LiDAR)

- Single photon detection

- APD Heterodyne/Geiger/Linear

- 22V CMOS devices

- TDI (Analog / Digital)

- Display / Spatial Light Modulator / LCOS

- Far infrared & high energy particle readout processors

- NIR, SWIR, MWIR, LWIR

- Gamma, X-Ray

- Visible, Low Light

hNon-Standard processes &

Unique & cutting edge applications often require specific technologies

- IR Detectors – InGaAs, QWIP, HgCdTe, SLS, PbSe, a-Si

- Bolometer

- Thermopile – Micrel

- PiN detector – Micron Semiconductor Ltd.

- Rad-hard CMOS – Honeywell 0.8 SOI

- CCD – Supertex 1.2um

jFoundry Experience

- TSMC 0.13um, 0.18um, 0.25um, 0.35um (includes their BCD [Bipolar, CMOS, DMOS] Power management technology)

- Tower/Jazz/TPSCo 65nm, 0.13um, 0.18um, 0.25um, 0.35um, and BiCMOS (Stitching, ITAR Compliant)

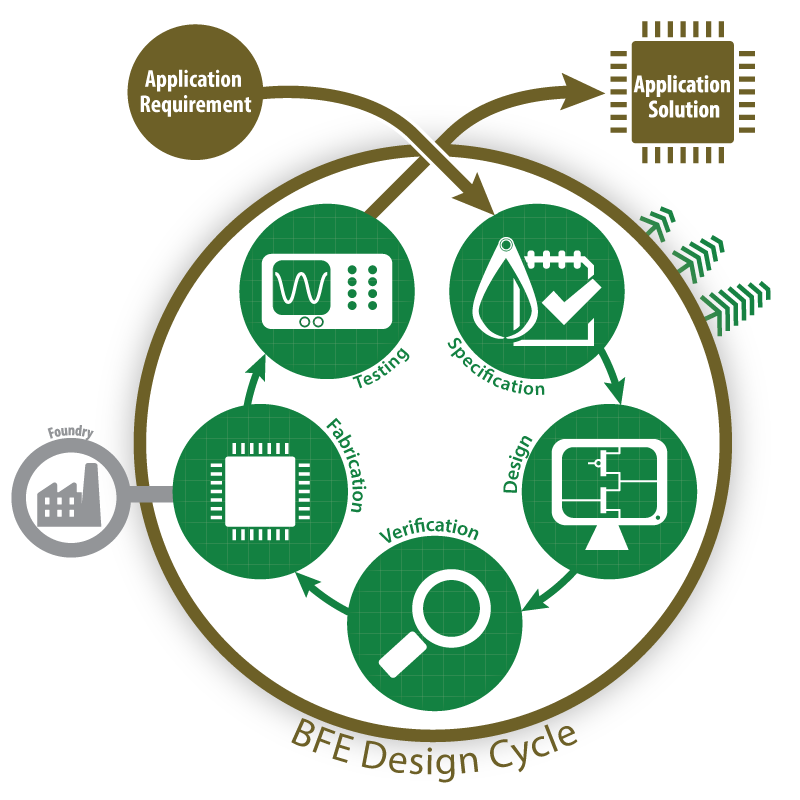

- Design Cycle Partner with TowerSemi

- IBM (corp. site) 0.13um (ITAR Compliant)

- Austria MicroSystems 0.35um

- Others include: AMIS (0.5um, 1.2um), CSMC (0.6um), Fujitsu (0.25um), HP (0.35um, 0.5um), Amkor (0.35um, 0.5um), Texas Instruments (0.8um, 1um), UMC (0.4um (5V))

jMask Types

- Full Mask Sets

- Stitching: Enables fabrication of large dice. A repeated exposure masking process that has its own complexities yield considerations.

- MPW: In addition to foundry specific multi-project wafer runs we have worked with MOSIS • Global Unichip • EUROPRACTICE.

hProcess Types & Materials

- CMOS

- CMOS/CCD

- Bi-CMOS

- BCD (Bipolar, CMOS, DMOS)

- CMOS-SOS

dDevice Protocols/Interfaces

- SERDES

- USB

- SPI

- LVDS

fCustom Test Systems

Performance built for your specific requirements.

- Wafer probing

- Testing at cryogenic temperatures

- PCB designs and interfaces using FPGA, CPLD and a variety of other components

- Solutions for system interface problems:

- High density interconnect

- Non-standard packaging

- Optics